Quality

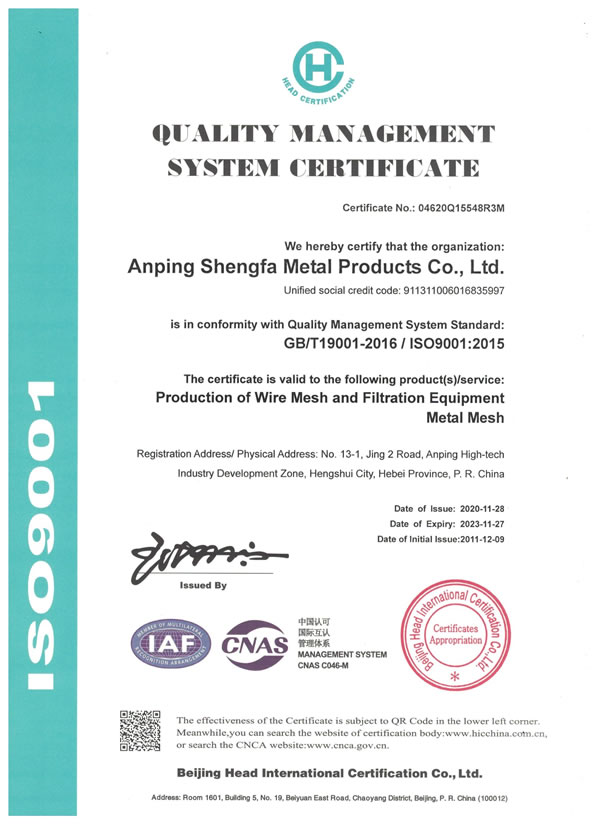

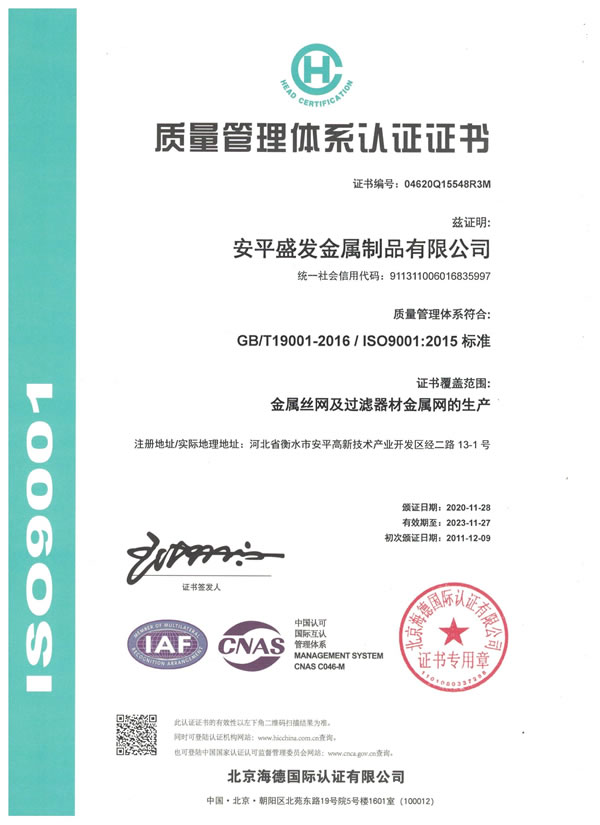

Our company is an ISO 9001 quality management system certification company and implements strict quality control standards in the production process. Continuous and effective inspections and inspections keep our product quality at an upper level.

Raw material control

The company controls the raw materials through a series of supply quality management measures such as procurement activity control, incoming inspection and supplier management.

Procurement activity control

The Purchasing Department cooperates with the Quality Management Department to prepare the procurement activity operation specifications according to the relevant regulations of the enterprise and the requirements for purchasing raw materials, and implement them in the procurement work. Sign the “Procurement Contract” and “Quality Assurance Agreement” with the qualified suppliers to ensure the timely supply and quality of the raw materials required by the company.

Raw material inspection management

The quality management department sets the wire inspection standard (physical properties, chemical composition), which is strictly implemented by the wire inspection department. The wire inspectors pass the wire inspection work, issue inspection reports, report the quality abnormalities in a timely manner, strictly control the quality of raw materials, and ensure that the raw materials meet the production needs of the enterprise.

Chemical Composition Test

Inspect Appearance

Physical Properties Test

Inspect Finished Products

Product quality control

In order to ensure that the product meets the customer's requirements, the factory products are inspected according to the corresponding standards. Since the quality of the product is greatly affected by the objective factors of the subject, in order to maximize the quality level of the enterprise products, the quality inspectors must be familiar with the quality inspection standards of the enterprise and strictly follow the quality inspection procedures to avoid the products with inspection errors.